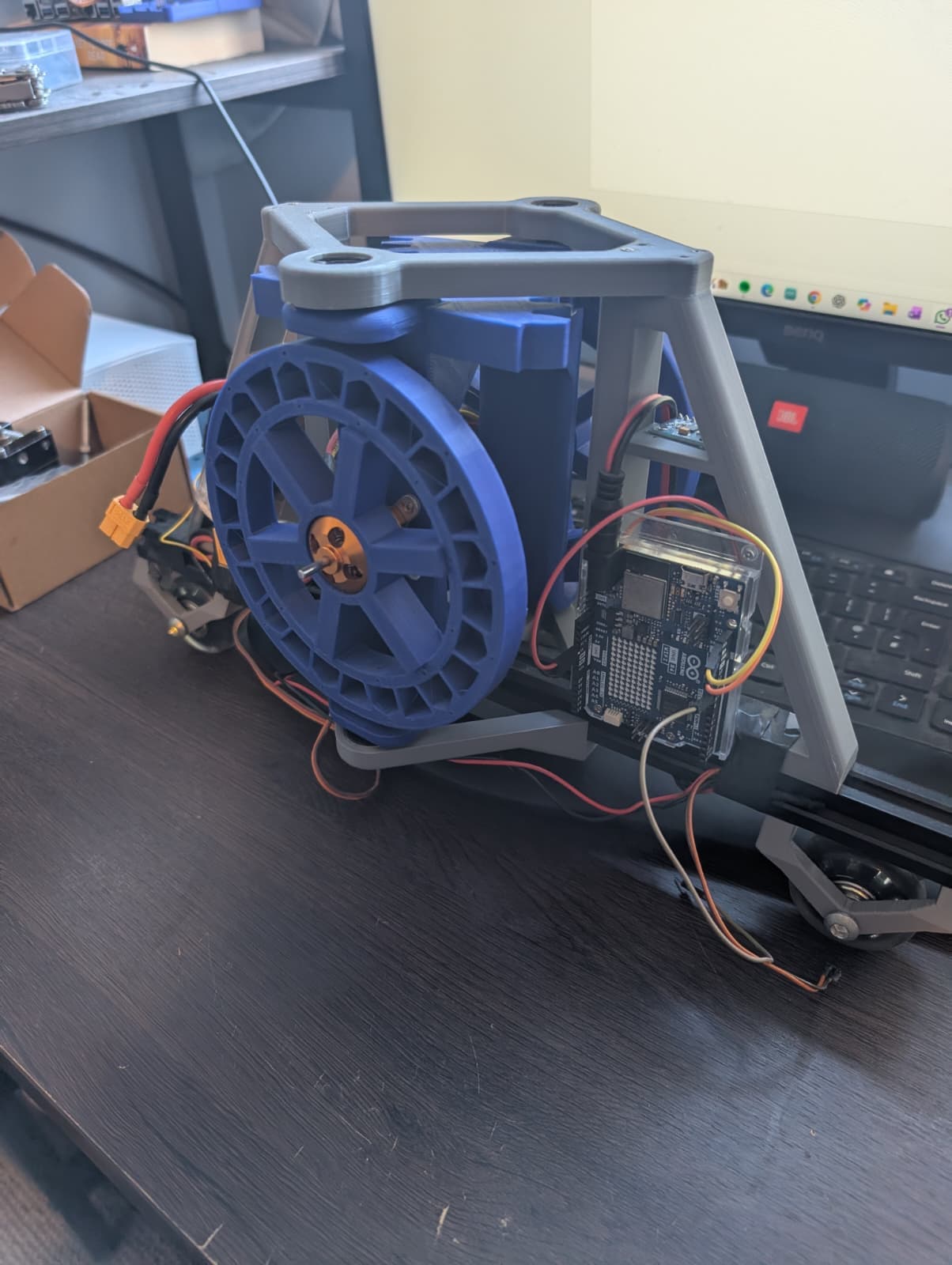

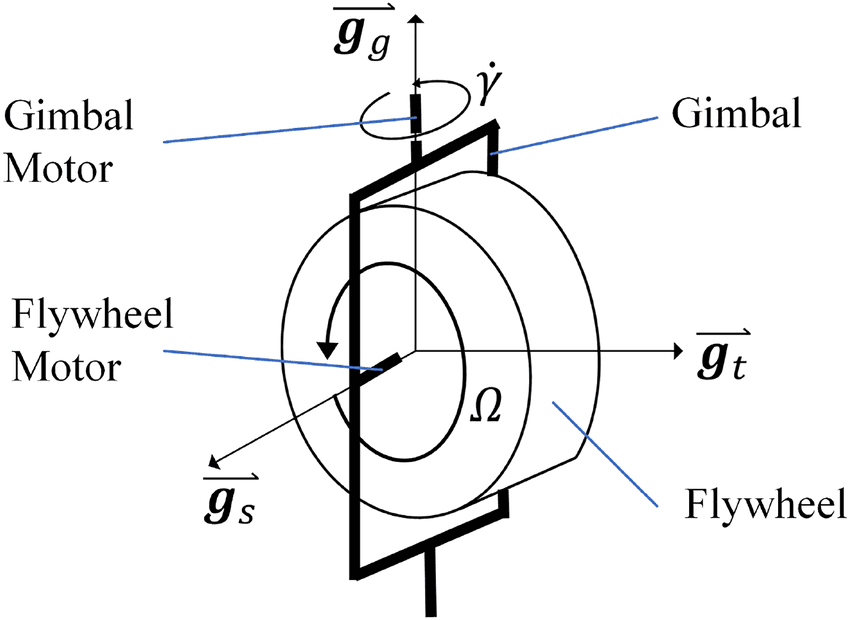

1) What is control-moment stabilisation?

Control-moment stabilisation uses a rapidly spinning flywheel mounted on a gimbal. The flywheel spins at a constant speed, storing angular momentum. When the gimbal rotates, the direction of this angular-momentum vector changes, and this change generates a torque perpendicular to both the flywheel spin axis and the gimbal axis. This torque can be used to counteract disturbances and stabilise the robot as it begins to tip.

- Flywheel speed sets how much stabilising authority you have

- Gimbal angle + rate controls the direction and strength of the corrective torque

- IMU feedback closes the loop (tilt angle + angular rate)

Control Moment Gyro Logic [ResearchGate]